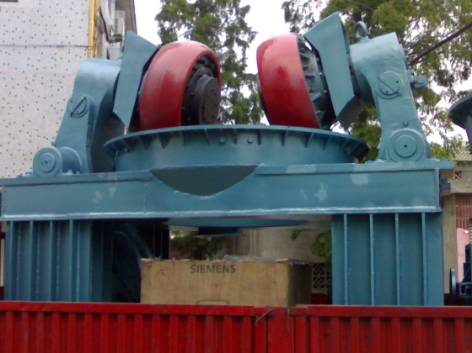

Vertical mill

Model HRM & PRM roller mill are new equipment designed by digesting and assimilating advanced technology introducted from other countries, It through grinding rollers to roll & press the materials(0-40mm)on the rotating grinding pan with pressure and grind them to be reached up to the relevant fineness. It has good advantages of high grinding efficiency, big drying capacity, product fineness is easy to be adjusted, low noise, low powder consumption, simple process flow, low abrasiveness, operating cost saving and ect.

Under the same process conditions and rotating speed, grinding pan diameter, material level, grinding roller pressure are the same, grinding efficiency of Model PRM roller mill can be raised more than 30%,average power consumption can be saved about 8.2%, and impact vibration of the overall unit could be obviously reduced.

With international advanced technology and nation leading manufacturing quality, it has passed the Ministry-level test and listed as state-level new product in 1995.

HRM PRM

Model HRM & PRM main technical data

Specifications

Capacity(t/h)

Power of Main Motor

Weight

HRM 1300

20~25

200

40

HRM 1700

40~48

400

70

HRM 1900

50~60

450

80

HRM 2200

70~90

630

150

PRM 1512

42~50

380

56

PRM 1714

55~65

450

75

PRM 1914

70~85

610

80

PRM 2216

95~115

745

160

Key words: Jiangsu Pengfei, Pengfei Group, Jiangsu Pengfei Group, Rotary Kiln, Kiln, Cement Mill, Tube Mill, Ball Mill, Direct Fired Drier, Dryer, Cooler, china cement equipment, Dust Collector, china Cement machiery supplier, Cement Technology, Cement Technique, Cement Grinding, Cement Engineering, Cement Machinery, Cement Equipment, Complete Set of Cement Equipment, Cement Mechanical Equipment, Complete Set of Cement Mechanical Equipment, Building Material Machinery, Building Material Equipment, Chemical Processing Equipment, Electric Equipment, Metallurgical Equipment, Mining Machinery Kiln, china cement machinery, Raw Material Mill, Slag Mill, Vertical Mill, Coal Mill, Grinding Equipment, Calcining Equipment, Kiln Equipment, Machinery, Equipment, Compound Fertilizer Equipment, Cement project, Product of crusher series, Blast furnace, Kiln project, Equipment installation, Installation company, China brand

....